Throughout the years we have supported our local ceramic industry based on the various needs of our community. These include technical design and prototyping support to glaze and color consultations.

Industry Support

3D printer

3D scanner

Accomplishments of Design Support

Ishoken / Tajimi City Pottery Design and Technical Center introduced a high-precision 3D scanner in 2020 with the aim to improve ceramic manufacturing technology. In 2021, Ishoken held collaborative study groups with the mosaic tile, ceramic tableware, and plaster mold industries in Tajimi to explore effective uses of 3D scanners.

Study Group with Tableware Manufacturing Industry

In the study group with the ceramic tableware industry we collaborated with the Ceramic Industry Cooperative Association from Takiro, Ichinokura, and Takata, and utilized reverse engineering techniques using the 3D scanner. We took 3D scans of existing products in production and reverse engineered the products to develop variations by changing size, form and by adding scanned textures as surface treatment. We also 3D scanned old products that have no plaster mold remaining.

Study group with Mosaic Tile Industry

In the study group with the Kasahara tile industry, CAD data of tile surfaces were made using scanned data from natural materials such as plants and stones. At the same time, we explored methods that could directly be used in the tile manufacturing process by using 3D printed resin components using the scanned data. We made tile prototypes using these resin components in the wet extrusion roller molding process and as molds for the dry press molding process in tile manufacturing.

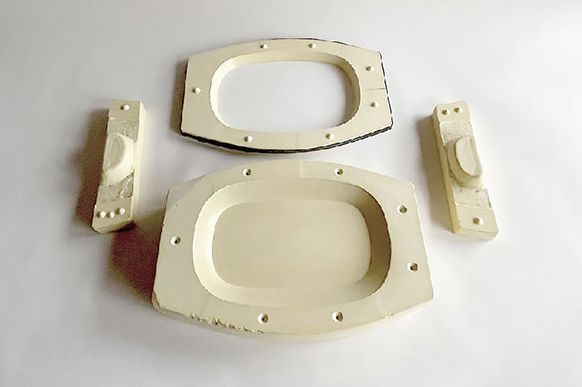

Study Group with the Plaster Mold Manufacturing Industry

In the study group with the Gifu Prefecture Plaster Mold Industry Cooperative Association Tajimi and Takiro Branch, we conducted various studies to further improve the plaster industry. We worked on improving accuracy of plaster modeling, shortening manufacturing time, and increasing work efficiency by using 3D scanners in the plaster mold manufacturing process, which is essential for Mino Ceramic production.

Tableware Safety Check

We provide technical food health and safety consultation for the ceramic tableware industry. We problem solve for product defects in the manufacturing process through to defaults in management systems. Initial consultation is free of charge. However, if you require official consultation documents or examination test result documents fees may apply based on our guidelines.)